Discover the Perks of Normal Strapping Machine Service for Enhanced Efficiency and Long Life

Routine strapping machine service plays a pivotal function in maximizing manufacturing operations. Companies that prioritize upkeep experience enhanced efficiency and reduced downtime. This positive strategy can aid identify prospective problems early, causing significant price financial savings. Several companies ignore the importance of consistent service. Recognizing the full range of advantages can reshape functional strategies and improve total productivity. What are the essential advantages that originate from this important technique?

Recognizing the Value of Strapping Machine Upkeep

While lots of organizations focus on manufacturing performance, the importance of strapping machine upkeep frequently goes overlooked. Routine upkeep is essential for assuring that strapping machines operate at peak performance levels. Neglecting this element can lead to unexpected break downs, which interfere with operations and increase downtime. Correct upkeep aids to recognize wear and tear before it escalates right into significant concerns, inevitably prolonging the life expectancy of the devices. Furthermore, regular checks guarantee that the machines create constant, premium strapping, minimizing the threat of damages to products during shipping and storage space. By investing time and sources into upkeep, companies can protect against costly repair work and cultivate an extra trusted production setting, thus supporting total functional objectives in the future.

Improved Operational Effectiveness

Boosted operational efficiency is a crucial advantage of routine strapping machine service. By guaranteeing that devices are well-maintained and functioning properly, companies can greatly reduce downtime brought on by inefficiencies or malfunctions. Regular servicing assists determine and deal with possible issues before they intensify, allowing seamless procedures. This positive technique implies that strapping devices run at peak performance, facilitating faster production cycles and minimizing the risks connected with unanticipated failures. In addition, a well-tuned machine can manage raised work without compromising quality, enabling better throughput. Ultimately, enhanced operational effectiveness translates right into a much more structured process, empowering firms to satisfy need successfully and boost total productivity in their product packaging procedures. Regular maintenance subsequently plays an important role in achieving functional excellence.

Price Cost Savings Through Preventative Upkeep

Routine servicing of strapping makers not just improves functional performance however additionally brings about substantial cost financial savings via preventative maintenance. By identifying and dealing with minor concerns before they rise right into major problems, companies can avoid costly repair services and downtime - strapping machine service. Routine examinations assist assure that elements function at peak performance, decreasing the risk of unanticipated failings that can interrupt manufacturing schedules. In addition, consistent upkeep can lead to extra reliable power usage, reducing utility costs gradually. Effective preventative upkeep techniques likewise enable organizations to prepare their spending plans much better, as expenses come to be extra foreseeable. Ultimately, buying routine service translates to lasting monetary benefits, making it a smart technique for any type of organization reliant on strapping equipment

Expanding the Life Expectancy of Your Devices

Normal maintenance checks play a crucial function in lengthening the life expectancy of strapping machines. Prompt repair work and using quality replacement components additionally guarantee that tools continues to be in suitable condition. By focusing on these practices, services can significantly improve the longevity and reliability of their strapping equipments.

Regular Upkeep Checks

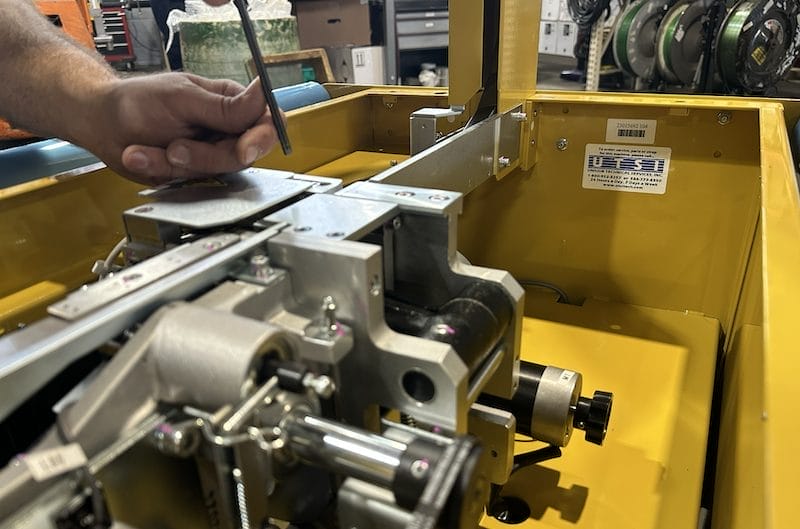

Strapping makers are made for toughness, disregarding normal maintenance checks can substantially reduce their lifespan. Constant examinations help identify damage before they rise into considerable issues. Normal maintenance warranties that all elements function at their best, lowering the danger of unforeseen break downs and boosting general efficiency. During these checks, components such as motors, belts, and sensors can be cleaned and lubed, protecting against rubbing and overheating. In addition, calibration of the machine setups can be performed original site to maintain exact operation, additional prolonging its longevity. By establishing a routine upkeep schedule, services can ensure their strapping equipments run effectively, conserving time and decreasing prices connected with tools failing. Ultimately, normal maintenance checks are essential for maximizing the life expectancy and dependability of strapping devices.

Timely Services Value

Prompt repair services are necessary for keeping the operational efficiency and longevity of strapping makers. When issues arise, resolving them without delay prevents minor problems from rising right into significant malfunctions that could result in pricey downtime. Regular maintenance enables operators to determine damage early, guaranteeing makers function effectively. Timely repair work aid maintain the high quality of strapping processes, which is important for item honesty and client complete satisfaction. Neglecting repairs can lead to raised energy usage and decreased efficiency, negatively influencing overall functional expenses. By focusing on prompt repair services, companies can extend the life expectancy of their strapping equipment, eventually securing their investment and enhancing total effectiveness in production lines. Constant focus to fixings is crucial to continual efficiency.

Top Quality Substitute Components

Purchasing top quality replacement parts is vital for prolonging the life expectancy of strapping devices. Premium parts ensure peak efficiency and dependability, minimizing the likelihood of malfunctions and pricey repair work. When inferior parts are used, they can trigger additional stress on the equipment, leading to even more frequent failures and a much shorter functional life. In addition, top quality replacement parts frequently feature far better service warranties, offering included assurance for drivers. Utilizing initial devices producer (OEM) components can better enhance compatibility and performance, making sure that the strapping machine operates as meant. Regular maintenance, integrated with the usage of top quality components, creates a collaborating result that takes full advantage of effectiveness, decreases downtime, and ultimately adds to the long-lasting productivity of business.

Reducing Downtime and Disturbances

As production routines come to be increasingly requiring, decreasing downtime my blog and interruptions in strapping machine operations is important for preserving performance. Normal maintenance of strapping devices can substantially reduce the likelihood of unexpected break downs. Arranged maintenance allows for very early discovery of potential problems, ensuring that all components work at their ideal. This aggressive approach not only protects against expensive stops in production however also extends the life expectancy of the devices. Furthermore, well-kept equipments operate efficiently, minimizing the chances of functional hiccups that might disrupt workflow. By purchasing routine service, companies can create an extra trusted manufacturing environment, improving general efficiency and meeting tight distribution target dates. Ultimately, decreasing downtime through regular maintenance methods is essential for maintaining efficient strapping operations.

Making Certain Regular Quality and Efficiency

While maintaining a high level of effectiveness, guaranteeing regular quality and efficiency in strapping equipments is crucial for any kind of assembly line. Routine maintenance plays an important duty in this facet, as it assists determine and correct prospective problems before they intensify. A well-kept strapping machine supplies consistent tension and protected seals, which are crucial for product packaging honesty. Additionally, regular performance lowers the risk of product damages throughout transportation, eventually enhancing client complete satisfaction. By buying regular maintenance, firms can enhance their strapping procedures, making certain that equipment runs at peak capacity. This positive technique not only extends the life-span of the devices but additionally assures that production requirements are met constantly, fostering dependability in the total manufacturing process.

Regularly Asked Questions

Exactly How Often Should Strapping Machines Be Serviced?

Strapping devices must ideally be serviced every six months to ensure peak performance. Nevertheless, use regularity and functional problems may necessitate more regular assessments, ensuring durability and efficiency in their operation.

What Are Usual Indicators That My Strapping Machine Demands Servicing?

Common indications that a strapping machine requires servicing consist of regular jams, inconsistent stress, uncommon noises, noticeable endure components, and unpredictable operation. strapping machine service. Dealing with these issues without delay can avoid additional damages and guarantee peak efficiency

Can I Execute Maintenance on My Strapping Machine Myself?

Yes, a person can execute fundamental maintenance on a strapping machine, such as cleaning and lubrication. For considerable repair services or maintenance, specialist assistance is suggested to ensure peak efficiency and longevity.

What Kinds Of Strapping Machines Require Service?

Different kinds of strapping devices, consisting of semi-automatic, automatic, and portable versions, need normal service. Each type might have unique maintenance requirements, yet all advantage from regular checks to ensure peak efficiency and longevity.

Are There Details Service Providers for Various Strapping Machine Brands?

Yes, particular provider usually concentrate on different strapping machine brands. These carriers have Visit This Link the needed competence and parts to guarantee peak repair and maintenance tailored to the one-of-a-kind needs of each brand's devices.

Enhanced functional efficiency is an essential benefit of regular strapping machine service. Routine servicing of strapping equipments not only improves operational effectiveness but also leads to substantial price savings via preventative maintenance. Routine upkeep checks play a necessary function in prolonging the life expectancy of strapping equipments. By establishing a regular maintenance schedule, businesses can assure their strapping makers operate effectively, conserving time and lowering expenses connected with equipment failure. Yes, a person can execute standard upkeep on a strapping machine, such as cleansing and lubrication.